Company Office Number:0755-27099734

Company landline:0755-27099734

Sales Mr. Chen:138 0270 8085

Sales Miss Hu:138 2351 9924

Company address:Room 403, Building A, No. 8 Xinhe Avenue, Xinqiao Community, Xinqiao Street, Bao'an District, Shenzhen

Email:facesun168@wickon.net

1、 Summary

Product Name | German WICKON furnace temperature tester |

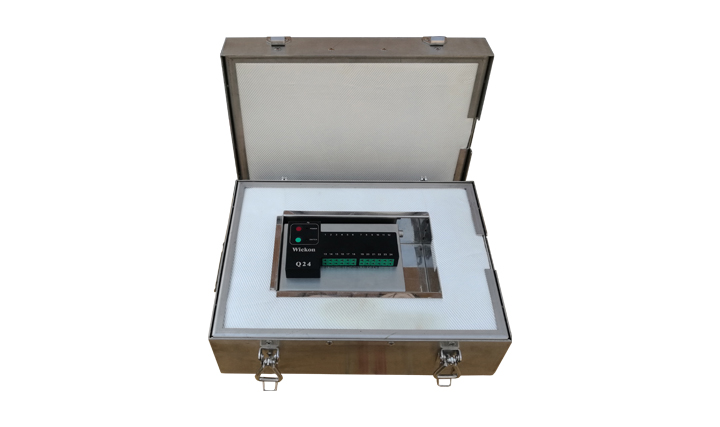

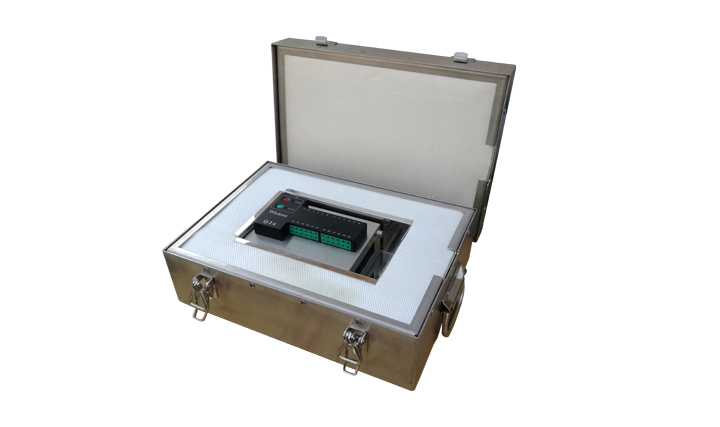

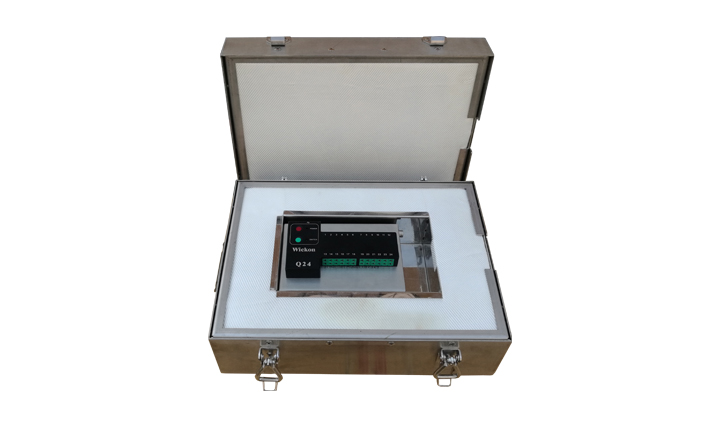

Structural appearance diagram |

|

Purpose/Function | Used for comprehensive temperature curve monitoring The brazing heat treatment thermometer is composed of a high-temperature resistant thermometer, an insulation box, and a high-temperature resistant thermocouple. Develop appropriate brazing temperature The speed of the mesh belt is the key to ensuring the quality of brazing. If the brazing temperature is too high and the mesh belt speed is too slow, it is easy to cause defects such as solder loss, dissolution, and fin bending Sink; The brazing temperature is too low, the mesh belt speed is too fast, and the workpiece has not yet reached the necessary brazing temperature. The uneven temperature in various parts can easily cause defects such as virtual welding, leakage, and discontinuous brazing joints. The German Wickon brazing heat treatment temperature measurement system can track and record the temperature, time, and temperature rise and fall rate throughout the entire production process of brazing heat treatment. Monitoring the temperature difference between different product thicknesses is the optimal production process for new products, providing data basis to ensure that the correct brazing temperature is achieved and not exceeded. With the intensification of competition in the automotive industry and the continuous improvement of automotive power performance, the entire industry has posed severe challenges to the heat dissipation performance, volume occupancy, and production cost of automotive cooling systems. Temperature curve control during brazing is the key to ensuring product quality. The Wickon furnace temperature tracker helps you adjust the temperature curve of the furnace, which can fully meet the temperature control needs of the production process. |

advantage | 1. Achieve the highest accuracy of ± 0.5 ℃ (full range) in electronic manufacturing. 2. The insulation box is made of black box material to ensure insulation quality and instrument temperature. Generally speaking, the outlet temperature is very low. Greatly extending the service life of the instrument. 3. By using polymer lithium batteries, it can be used continuously for more than 72 hours, not only saving your company's battery costs, but also saving your company's time and minimizing resource waste. 4. The software has powerful functions, SPC analysis, and so on. 5. There is no need to test the air temperature. 6. High stability. 7. It has a considerable lifespan, and currently there are many WICKON devices that have a lifespan of over ten years. 9. Multi channel (6, 7, 10, 12, 15, 24, 32) recorders can obtain the temperature curves of the most components. 10. It can test 24 sets of data simultaneously, greatly saving testing time. 11. Direct USB communication with the PC ensures fast data downloads 12. The powerful Insight software now has the ability to measure fluctuations 13. Choose the world's smallest MINI, which is the industry's smallest appearance, largest memory, and most comprehensive top-level furnace temperature tracker 14. Software functions A) Can analyze high/low temperature, temperature time, slope calculation, rise/fall calculation, and different peaks and peak differences; B) Can calculate heat treatment parameters such as heating, holding time, cooling rate, etc; C) Can draw the temperature curve of the entire process; D) Can directly print furnace temperature uniformity test reports or output electronic test reports; E) Simulated curve function, process optimization, testing date and time F) Output of company name, product name, and note information processing G) Software clearing instrument memory data method H) Time compensation I) Temperature statistics J) The software is licensed for permanent use without the need for regular decryption, and can be upgraded for free for life to meet the needs of customers enjoying the latest and most comprehensive process analysis items K) Can continuously test 24 sets of data L) Can trace, supplement, and modify ISO-9000 file reports M) Can insert test product images N) The curve can move up, down, left, right, and can also select points for local correction The analysis column can be completed in one interface without the need to switch between multiple screens 1) Equipped with PWI judgment function, it automatically captures process deviations and clearly identifies the area where the high-temperature furnace problem is located, with a red warning mark. |

WICKON system service and warranty | Each Wickon system comes with a one-year warranty period. In addition to the warranty, we also offer annual maintenance and recalibration contracts, which include free software updates and equipment leasing to relieve your worries |

2、 Principle:

(1) Data logger

The Wickon data recorder is currently the most accurate recorder in the field of temperature measurement in the high-temperature industry. It has an accuracy of ± 0.5, a resolution of 0.1 degrees, and a storage capacity of over 400000 points, thus providing detailed information for deep analysis of processes. The feature of direct USB communication enables information to be transmitted from the data logger to the computer PC as quickly as possible

(2) Insulation box (special insulation box for anti scalding aviation insulation cotton is optional)

The ultra lightweight and high-efficiency insulation materials used by Wickon ensure that the insulation box can also protect the data logger during the hottest temperatures. The combination of insulation material and a very thin stainless steel shell means that the insulation box absorbs the least amount of heat from inside the furnace, but it is also very sturdy enough to withstand the most extreme usage. Used in lead-free soldering to protect recorders at high temperatures. It adopts the same insulation technology as the "black box" flight recorder on the aircraft and is enclosed in a sturdy stainless steel shell

(3) The basic principle of thermocouple temperature measurement

Solder two different materials of conductors or semiconductors A and B together to form a closed circuit. When there is a temperature difference between the two contacts of conductors A and B, a temperature difference electromotive force is generated between the two, which is called the thermoelectric effect. Thermocouples work by utilizing this effect.

(4) Insight software features

guide

All commonly used functions are based on guides, such as tolerance curves and process files. Even for quite complex analysis, the wizard can guide you step by step through the temperature curve testing process, ensuring completion of all stages of testing and saving training time.

alert

New alert features can be used to alert you when an error occurred. An alert can be set for any numerical analysis domain. If a certain value exceeds the limit, a PWI alarm will appear on the screen to enable you to quickly identify the problem.

SPC calculation of historical data

Insight software allows users to conveniently and quickly use temperature curve historical data for SPC calculations. In this way, the stability and capability of the welding process can be tested.

Detailed structure:

1: Wickon packaging box

2: Instruction manual

3: Insulation box

4: Data logger

5: High temperature gloves

6: Data cable

7: Insight software

8: Thermocouple

9: Factory calibration report

specifications

project | Content | |

Product Name | Furnace temperature curve tester | |

temperature range | -200℃--1370℃ | |

working temperature | 0-105℃ | |

Total storage capacity | 4,000,000points | |

Battery | No need for deliberate charging, automatically replenishing power, truly achieving 365 without charging. | |

Number of channels | 6、7、10、12、15、24、32 | |

Sampling interval | 0.05s~86400s(can be set according to testing requirements) | |

Thermocouple type | K | |

accuracy | ±0.5 ℃ | |

Battery type | Rechargeable polymer lithium batteries | |

Weight of insulation box (kg) | Depending on different specifications and heat resistance time | |

Insulation box size (mm) | Different specifications and heat resistance time determine | |

WICKON - the world's most professional temperature curve testing system

Name: Wickon Q series temperature curve recorder

Brand: WICKON

Origin: Germany

The WICKON system consists of a programmable data logger, an insulation box (consisting of an efficient insulation layer enclosed in stainless steel), thermocouples (which can be attached to the product), and Insight analysis software.

The main application areas of the WICKON system include metallurgy, automotive, aerospace, glass, ceramics, electronic reflow soldering, wave soldering, powder, paint, food, and so on.

Usage steps:

1. Settings: Reset the data logger and connect the temperature measurement probe to the product.

2. Traversing process: Place the recorder in an insulated box. Make the recorder travel through the high-temperature furnace with the product to record millions of temperature readings.

3. Analysis: Use Insight software to accurately understand what is happening inside the furnace.

As a global industry leader, many of WICKON's clients in Germany are leaders in their respective industries, such as Siemens, Tianhong, Changhong, Oriental Communication, Motorola, Henkel Lotte, Weichuangli, Global Instruments, Delta, TCL, and Ophiguang Group

Shenzhen Shihan Electronic Technology Co., Ltd. Chen/R138 0270 8085

SHENZHEN WICKON ECONIC TECHNOLOGY CO., LTD

Address: Room 2202, Building A, Central Mingzuo, Haoxiang Road, Shajing Town, Bao'an District, Shenzhen

Http://www.wickon.net E-Mail: facesun168@wickon.net

Copyright 2021 Shenzhen Shihan Electronic Technology Co., Ltd. Main website keywords:Furnace temperature tester,KIC furnace temperature tester, WICKON furnace temperature tester, DATAPAQ furnace temperature testerWebsite production: Shenzhen Shihan Technology