Company Office Number:0755-27099734

Company landline:0755-27099734

Sales Mr. Chen:138 0270 8085

Sales Miss Hu:138 2351 9924

Company address:Room 403, Building A, No. 8 Xinhe Avenue, Xinqiao Community, Xinqiao Street, Bao'an District, Shenzhen

Email:facesun168@wickon.net

The temperature curve and furnace temperature tester is a new type of product in the manufacturing industry. The furnace temperature tester has brought great convenience to our production and life, and can be applied in many industries such as reflow soldering, wave soldering, color spraying, ceramic sintering, chemical engineering, food processing, etc. It plays an important role. So what benefits and conveniences does the furnace temperature tester bring us? Why do companies of a certain scale use furnace temperature testers? How much impact does the furnace temperature tester have on production?

There is also considerable controversy in the entire industry regarding the purchase of furnace temperature testers. So today, the editor will analyze the impact of furnace temperature testers on production and quality from their own perspective.

The concept of furnace temperature tester was first proposed by European and American countries and was first applied in the SMT industry. Over thirty years ago, Americans on the other side of the ocean were often deeply troubled by the quality of surface mount processing products. Why is the yield rate so poor when many products have no damage to their appearance after being baked? Who is at fault for the product that one has worked hard to create? Uncle Tom roared angrily, "Where are the monsters coming out to suffer death?"

At this time, the concept of temperature control first appeared in front of these capitalists. It turned out that changes in temperature had such a profound impact on products, and it was at this time that furnace temperature testers emerged. As research deepens, the impact of temperature changes on products gradually emerges before people's eyes.

Baking at too high a temperature can change the internal structure of the product, while at too low a temperature, the product cannot be welded. Whether it is the length or speed of heating time, it seriously affects the quality and even the service life of the product. At this moment, the bosses suddenly realized that this invisible and intangible thing was actually a guy who had consumed thousands of their own raw materials. So in just a few short years, production lines across the United States, whether large manufacturing or small processing plants, have all used this cute little guy "furnace temperature tester". As a result, a large number of furnace temperature tester companies such as KIC and Wickon have emerged.

People in the manufacturing industry know that foreign customers have the strictest requirements. Before placing an order, they are required to use various equipment, instruments, and third-party reports. There used to be a globally renowned bicycle manufacturer who received an order from a foreign customer and was asked to use a furnace temperature tester. They hurriedly came to inquire about the procurement and training of furnace temperature testers. After learning about the function of furnace temperature testers, they finally exclaimed that the reason for the wear and tear over the years was here.

The furnace temperature tester may seem small but contains enormous energy. Its small body reproduces these complex circuits and chips, and its powerful tracking and analysis software can help you design almost perfect temperature curves, giving your product a beautiful appearance and exquisite quality.

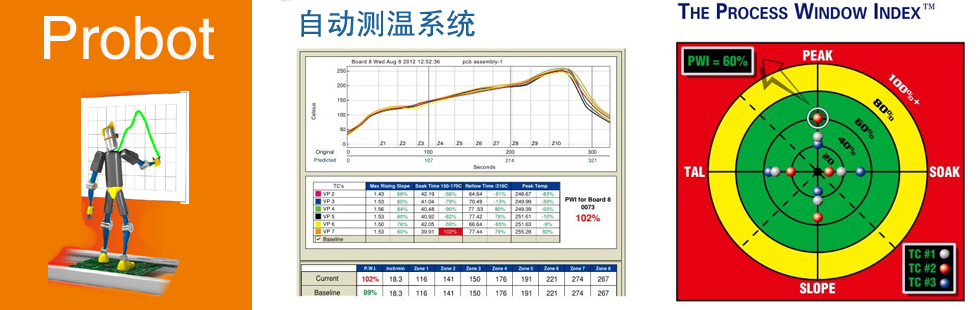

With the development of furnace temperature testers and the continuous improvement of various functions, furnace temperature testers are not only capable of measuring temperature changes. Taking KIC as an example for advanced furnace temperature testing, the measured data can also be programmed to check PWI, and whether it meets the process requirements is clear at a glance. More advanced features such as Process Window Index and Navigator Power Key can be achieved through KIC and Wickon's furnace temperature testing. Navigator Power Key is an optimization analysis software, commonly referred to as Optimization Key. With this key, as long as we meet the requirements of our own product craftsmanship, it will automatically find a matching furnace temperature setting for you. Even novice employees can take the customer's requirements and input the required data into the software, and Navigator Power Key will automatically match and adjust it, greatly saving us time and error rates in editing the process.

Meanwhile, the application of furnace temperature testers is also very wide, including reflow soldering, wave soldering, food processing, hardware, ceramic sintering, and color spraying.

Using instruments is to help you gain a broader world, not to waste your money. Let's consider the role of a furnace temperature tester from a different perspective.

Thank you for your review. This article is edited by Shihan Electronics

If there is any infringement, please contact me to delete or modify @ KIC @ wickon

No unauthorized reproduction or modification of article content

Email: 18688866491@163.com

Or call me at 18688866491

Copyright 2021 Shenzhen Shihan Electronic Technology Co., Ltd. Main website keywords:Furnace temperature tester,KIC furnace temperature tester, WICKON furnace temperature tester, DATAPAQ furnace temperature testerWebsite production: Shenzhen Shihan Technology